Risk Analysis Back End – Production

ISO 14971, Patient, Production, Risk Analysis, User

In a previous Device Tips, I discussed the value of putting mitigations derived from Risk Analysis into the product requirements and specifications, and confirming that the mitigations have been implemented, operate correctly and are effective to mitigate the specified risks during Design Verification and Design Validation (Design V&V).

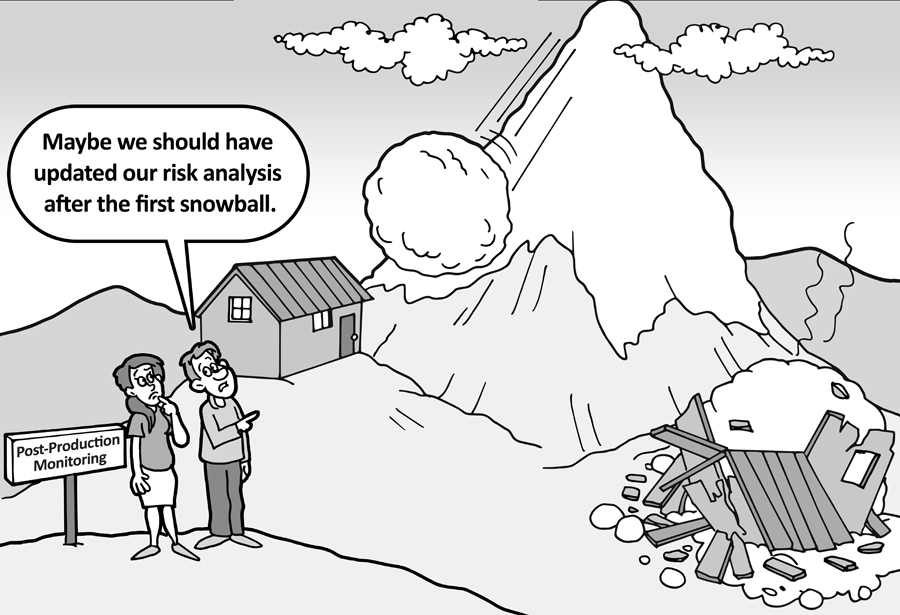

But the rubber really meets the road in Risk Management when product starts being used by real Users on real Patients in the real world. This is where the “back end” of Risk Management is vital to ensuring safe and effective products, and satisfied Users and Patients.

The fundamental International Standard for application of risk management to medical devices, ISO 14971, contains the following requirement:

The manufacturer shall establish, document and maintain a system to collect and review information about the medical device or similar devices in the production and the post-production phases.

And while this is perhaps the most important stage of the overall Risk Management process, for a variety of reasons many Medical Device companies struggle with how to “close the loop” and feed post-production information regarding risk, back into the design and development process in a meaningful way that achieves the goals of safer products and thus more satisfies Users and Patients.

Here’s the tip:

Establish a process to evaluate post-production feedback from Users, review the data for potential implications and update the risk analysis as needed. Once the results are in, do the right thing.

More Info

Collecting and evaluating post-production data on your product is critical to maintain the life cycle of risk management. There are several important steps to creating a successful process:

- Obtain post-production data from multiple sources including customer complaints, customer returns, user surveys and service reports.

- Design an effective system to manage the data as it is collected, including identification of the product, the type of problem reported/identified and any action taken to address the reported problem. Also identify whether the problem is a potential patient or user risk, a usability issue or is software related. This will allow for easier analysis of the data.

- Periodically analyze the post-production data to determine to identify any risks.

- If risks are identified, review the Risk Analysis to determine whether :

- Any previous unrecognized hazards or hazardous situations may occur and/or

- the estimated risk(s) arising from a hazardous situation is/are correct or need to be updated.

- After reviewing the Risk Analysis and any other data from the post-production monitoring of your product’s performance, take the necessary action to continue providing a safe and effective product for your customers.