IEC 60601-1 3rd Edition, Part 4 – Risk Management

Design, IEC 60601-1 3rd Edition, Risk Management

In a previous Device Tip I mentioned that one of the key Process Collateral Standards of IEC 60601-1 3rd edition is ISO 14971, Risk Management. In fact. I often refer to Risk Management as the “backbone of the 3rd Edition” since it runs through the General Standard (IEC 60601-1), all the Collateral Standards and all of the Particular Standards I have dealt with.

So here’s the tip:

Integrate Risk Management as a standard part of the Design Control, Production and Post-Production processes.

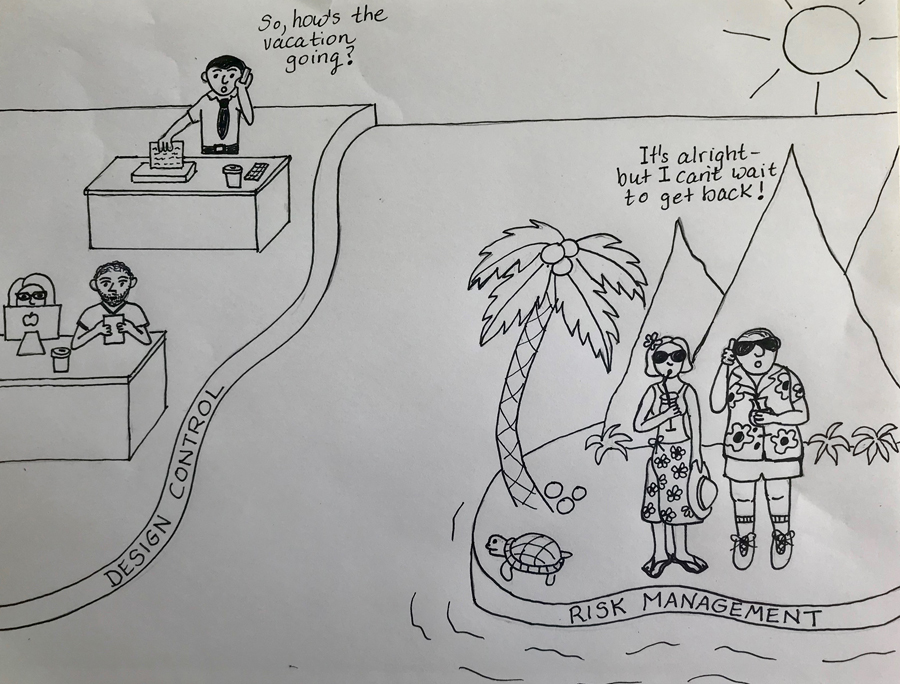

In the past many companies (and Design Teams for that matter) have treated Risk Management as an island, just outside the Design Control process. A place one visits occasionally but doesn’t really live there. Once the Risk Analysis is done, it was left on the island and never looked at again (“whew, glad we got that Risk Analysis done so we can get back to designing”).

The following table shows how Risk Management can be integrated as a standard part of the Design Control, Production and Post-Production processes.

| Product Life-Cycle Element | Risk Management Process Element |

|---|---|

| Design and Development Planning | Risk Management Planning |

| Design Output | Risk Analysis |

| Design Review | Risk Analysis Review |

| Design Verification | Verify implementation and effectiveness of Risk Mitigations |

| Design Validation |

|

| Design Transfer | Process FMEA |

| Design History File | Risk Management File |

| Design Changes: Design Change impact assessment | Design Change impact to Risk Analyses |

| Production | Implement and verify effectiveness of Process Risks Mitigations |

| Post-Production |

|

The following table provides a more detailed view of how Risk Management can be integrated as a standard part of the Design Control, Production and Post-Production processes

| Product Life-Cycle Element | Risk Management Process Element |

|---|---|

| Design and Development Planning | Risk Management Planning |

Design Input:

|

Risk Analysis Input

|

| Design Output: Product Design |

|

| Design Review: | Risk Analysis Review |

Design Verification:

|

|

Design Validation:

|

|

| Design Transfer: Manufacturing process flowchart | Process FMEA |

| Design History File | Risk Management File |

| Design Changes: Design Change impact assessment | Design Change impact to Risk Analyses |

| Production |

|

| Post-Production |

|